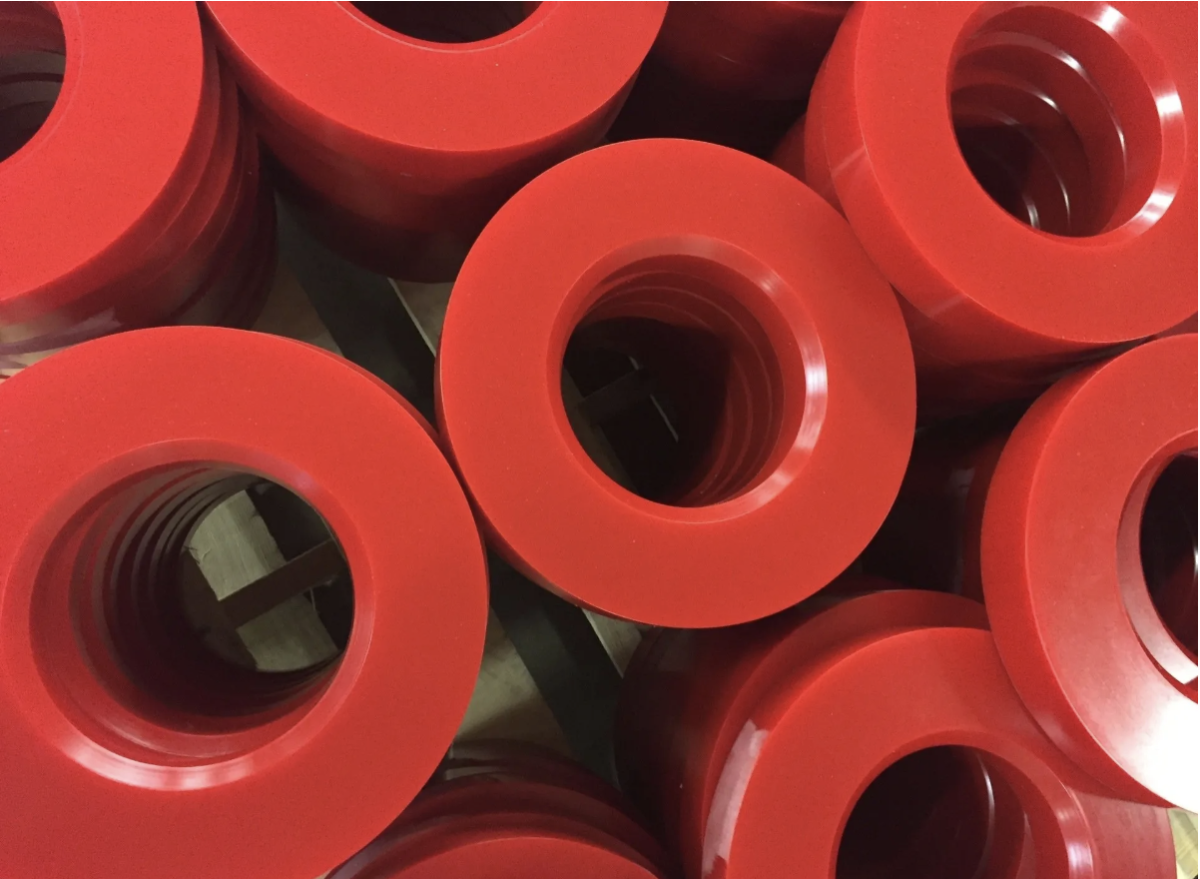

Polyurethane molding is a type of pressure-sensitive plastics molding that is often used for larger-scale applications, such as automotive parts and furniture, but can also be used for smaller objects like toys and medical devices. It is a thermoset plastic, meaning it can be reheated and reshaped multiple times. This makes it a versatile material for creating products with complex shapes. Raw polyurethane is melted and injected into a mold, where it is allowed to harden. This is a process that creates a plastic or rubber cast often used for mass production.

How to Reduce Drag on Polyurethane Molding

Every day we are affected by polyurethane molding, whether we realize it or not. When we step on our floors or sleep under a roof, or even get into the car, polyurethane is the main ingredient keeping everything together. Even though polyurethane is very efficient in terms of air and fluid flow, it has one significant drawback: It is a very draggy material. This means that it takes a lot of energy to move it around, which can significantly reduce the speed and efficiency of production lines. There are a few ways that you can reduce the drag on your polyurethane-molded parts.

1. Ribs

One way to reduce drag is to add ribs or other features to the part that will disrupt the airflow. Ribs and ridges can alter the airflow around the object, in turn lessening the drag.

2. Surface Coating

You can also add a surface coating, which will reduce the amount of drag. The best surface coating to look into is a simple lubricant. A good lubricant will help to reduce the friction between the polyurethane and the machine parts, making it easier to move.

3. Low-Profile Design

If you are a machinist, you can also design the part so that it has a low profile. This will help reduce the amount of drag created as the piece moves through the air.

4. High-Quality Polyurethane

Another way to reduce drag is to use a higher-quality polyurethane. A higher-quality polyurethane will be less draggy than a lower-quality material. While less drag can be achieved with lower quality, the process of lessening that drag will take away precious machining time. So sometimes, this simple change of increasing the quality can be the key to unlocking a less draggy, faster process.

5. Adjust Machine Settings

Finally, you can also adjust the machine settings to optimize the flow of polyurethane. This will help reduce the amount of energy needed to move the material.

Streamline Your Molding and Machining

Using these tips, you can help reduce the drag on your polyurethane molding, making it easier and more efficient to produce your products. If you are interested in outsourcing your molding, or learning from a company that has been a trusted machining staple throughout the US, check out the experts at Ephrata Precision Parts. Your polyurethane molding process should be smooth and not draggy. To speed up your processes and create amazing products, just follow these steps, and you’ll be quickening your machining process in no time! This article is accurate and true to the best of the author’s knowledge. Content is for informational or entertainment purposes only and does not substitute for personal counsel or professional advice in business, financial, legal, or technical matters.